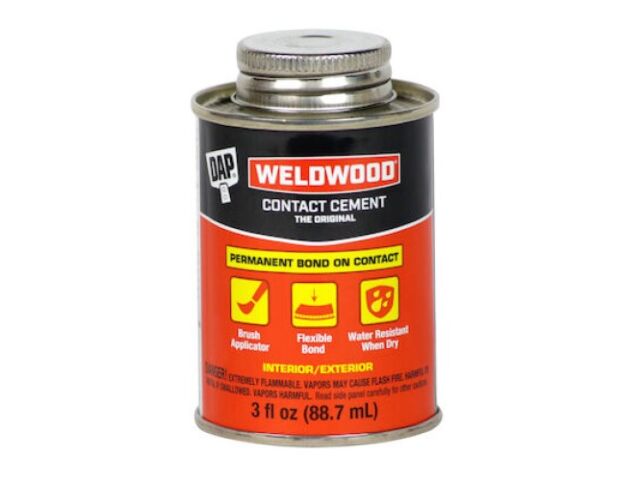

DAP® 00273 Weldowood Original Contact Cement

DAP® WELDWOOD® Contact Cement is a multi-purpose neoprene rubber adhesive that forms instant, high-strength bonds on a variety of surfaces. Offers hundreds of uses for the home, office, and workshop. Forms strong bonds on contact to eliminate the need for clamps, temporary fasteners, and long set times.

DAP WELDWOOD Contact Cement spreads easily, quickly dries tack-free, and offers a 20 minute open time. When parts are pressed together, bonds form instantly. Resists the effects of heat, water, weather. Interior/exterior use.

- High strength, permanent bond

- Can be used on a variety of surfaces

- Strong based adhesive resists curling

| Type | Multi-Purpose |

|---|---|

| Size | 3 fl. oz. |

| Color | Tan |

| Brand | DAP |

| Material | Solvent-Based |

| Manufacturer Code | 00105 |

Surface Preparation & Application: The surfaces to be bonded must be clean, dry and free of all foreign material. Previously applied finishes should be removed and the parts must be pre-fitted before any adhesive is applied. The temperature of the adhesive, the surfaces being bonded, and the working area should be at or above 65°F.

Application:

- Apply an even coat of adhesive to both surfaces. If the dried surface has a glossy appearance sufficient adhesive has been applied. If substrates are porous more than one coat may be required.

- Allow both surfaces to dry 60-70 minutes (dependent on temperature and humidity). Dry Contact Cement will feel tacky and appear glossy. If surfaces are not assembled within 2-3 hours, applying an additional coat of Contact Cement can reactivate adhesive.

- Align surfaces into exact position and press together, moving from one end to the other to avoid bubbles. Contact cement bonds permanently with pressure and work cannot be shifted into place after firm contact is made. For large areas, use dowels to prevent surface contact while positioning surfaces. Place dowels every 6 to 12 inches. Remove dowels as surfaces are pressed together.

- Once surfaces are joined, a minimum of 25 lbs. per square inch of pressure should be evenly applied to surface starting in center and working out to edges. This is equivalent to 75 lbs. of pressure being applied to a 3-inch “J” roller. Apply as much pressure as possible, being careful not to crush the core materials. Insufficient pressure may allow blisters or bubbles to form later. This can be readily achieved if bonded surface is on a solid waist-high workbench.

- No clamping required. Contact Cement bonds permanently when sufficient pressure is applied and reaches maximum holding strength in 7 days.

- Trimming or finishing operations may be performed immediately after bonding. Allow at least 72 hours of curing before exposing bonded assemblies to direct sunlight or temperatures over 150 °F (66°C).

Clean Up: Clean excess wet adhesive from surfaces and tools with mineral spirits. Dried adhesive must be cut or scraped away. Clean hands with warm water and soap. DO NOT use solvents to remove product from skin. Store container in cool, dry place away from extreme heat or cold.