Darien, CT

Address: 181 West Ave, Darien, CT 06820

Bethel, CT

Address: 9 Taylor Ave, Bethel, CT 06801

Boston, MA

Address: 355 Newbury St, Boston, MA 02115

Branford, CT

Address: 25 E Industrial Rd, Branford, CT 06405

Danbury, CT

Address: 59-67 Federal Rd, Danbury, CT 06810

Fairfield, CT

Address: 1139 Post Rd, Fairfield, CT 06824

Hampton, NH

Address: 848 Lafayette Rd, Hampton, NH 03842

Lewisboro, NY

Address: 386 Smith Ridge Rd, South Salem, NY 10590

Madison, CT

Address: 85 Bradley Rd, Madison, CT 06443

Middleboro, MA

Address: 149 Everett St, Middleboro, MA 02346

New Bedford, MA

Address: 1193 Ashley Blvd, New Bedford, MA 02745

New London, CT

Address: 308 S Frontage Rd, New London, CT 06320

New Milford, CT

Address: 140 Danbury Rd, New Milford, CT 06776

Newburyport, MA

Address: 201 Merrimac St, Newburyport, MA 01950

Newton, MA

Address: 50 Needham St, Newton Highlands, MA 02461

Newtown, CT

Address: 14 Church Hill Rd, Newtown, CT 06470

Niantic, CT

Address: 28 Hope St, Niantic, CT 06357

Norwalk, CT

Address: 149 Westport Ave, Norwalk, CT 06851

Orange, CT

Address: 131 Boston Post Rd, Orange, CT 06477

Plymouth, MA

Address: 58 Shops at Five Way, Plymouth, MA 02360

Portland, ME

Address: 1037 Forest Ave, Portland, ME 04103

Portsmouth, NH

Address: 620 Peverly Hill Road, Portsmouth, NH 03801

Saco, ME

Address: 35 Scamman St, Saco, ME 04072

South Portland, ME

Address: 153 Ocean St, South Portland, ME 04106

Stamford, CT (Harvard Avenue)

Address: 87 Harvard Ave, Stamford, CT 06902

Stamford, CT (High Ridge Road)

Address: 921 High Ridge Rd, Stamford, CT 06905

Stratford, CT Commercial Paint Center

Address: 160 Avon St, Stratford, CT 06615

Phone:(203) 814-3050

Store hours:

Mon - Fri7am - 5pm

SatClosed

SunClosed

HolidaysClosed

Set as default storeTrumbull, CT

Address: 921 White Plains Rd, Trumbull, CT 06611

Waltham, MA

Address: 14 Warren St, Waltham, MA 02453

Westport, CT

Address: 877 Post Rd E, Westport, CT 06880

Wethersfield, CT

Address: 669 Silas Deane Hwy, Wethersfield, CT 06109

Wilton, CT

Address: 129 Danbury Rd, Wilton, CT 06897

Woburn, MA

Address: 116 Cummings Park, Woburn, MA 01801

Yarmouth, ME

Address: 412 Route 1, Yarmouth, ME 04096

- Home

- Shop

- Paint

- Floor Coatings & Paint

- Epoxy Floor Coatings & Paint

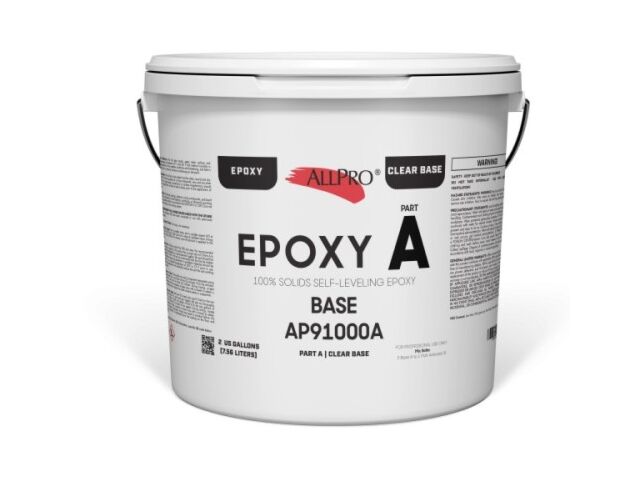

- AllPro Epoxy Floor Coatings, 100% Solids, Self-Leveling, Part A, Clear Base, 2 Gallon

- AllPro Epoxy Floor Coatings, 100% Solids, Self-Leveling, Part A, Clear Base, 2 Gallon

AllPro Epoxy Floor Coatings, 100% Solids, Self-Leveling, Part A, Clear Base, 2 Gallon

*NOTE: Must purchase PART B activator, separately. Part A will not work individually.

ALLPRO® 100% Solids Self-Leveling Epoxy Floor Coating is a two-component, high performance chemical resistant… Show more

*NOTE: Must purchase PART B activator, separately. Part A will not work individually.

ALLPRO® 100% Solids Self-Leveling Epoxy Floor Coating is a two-component, high performance chemical resistant gloss epoxy specially formulated for applications where a high build, seamless, and abrasion resistant floor is required. It provides a low VOC and low odor gloss coating with excellent chemical, abrasion, and stain resistance. It can be applied in a solid color or used as a primer and color basecoat for chip or quartz decorative floors.

Recommended Substrates for interior properly prepared concrete floors, warehouses, kitchens, restrooms, and garage floors. Not recommended for exterior use as accelerated chalking & fading will occur.

Part B Activator Options:

- AP91010B Standard Activator

- AP91011B High Density Activator

- AP91013B Moisture Vapor Barrier- Primer Coat

- Interior only

- Part A only, Part B activator sold separately (Moisture Vapor Barrier, Standard Activator, High Density Activator)

- Color pod selections, sold separately

- Finished product or color basecoat for chip or quartz decorative floors

- Scrub & abrasion resistant

- Chemical & solvent resistant

- Low VOC and low odor

- High build - up to 24 mils

- Integrated cove base with Thixo additive

- Can be mixed with aggregate to create a slurry up to 1/4 in. thickness

| Type | Interior |

|---|---|

| Size | 2 Gallon |

| Color | Clear |

| Brand | AllPro |

| Color Family | Clear |

| Material | 100% Solids Epoxy |

| Manufacturer Code | AP-91000-A |

Surface Condition: The surface to be coated must be clean, sound, and dry. Remove dust, dirt, laitance, grease, oil, curing compounds, waxes and any other contaminants. Any rough spots, projections or surface imperfections should be removed or patched to achieve a level surface prior to the application of any coatings.

Old or Previously Coated Concrete: Concrete surface must be cleaned and mechanically prepared using shotblasting, sand blasting, and/or diamond grinding. All oils, sealers, curing agents, waxes and fats must be removed prior to product application. Do not apply onto wet substrates. Chloride, moisture, and pH levels should be checked prior to application. If the moisture content exceeds 4%, one of our moisture vapor barrier activators must be used. All cracks, divots, depressions, or surface imperfections should be filled and repaired prior to application. Divots or depressions must be filled with a slurry of AllPro Epoxy and sand or aggregate, AllPro Crack Filler or an approved patching compound.

New Concrete: New concrete should be allowed to cure for a minimum of 30 days. Compression resistance of concrete must be at least 25 MPa (3625 lbs./inch2) after 28 days and traction resistance must be at least 1.5 MPa (218 lbs./inch2). Shotblasting, sand blasting, and/or diamond grinding is required to remove the surface laitance that appears during the concrete finishing and curing process.

Surface Profile: All existing coatings, laitance, curing compounds, and bond breakers must be removed via shot blasting, scarifying or diamond grinding and provide a suitable profile in accordance with ICRI CSP-2 or CSP-3, but not to exceed the thickness of the coating system. Abrasive blasting or grinding is to leave the concrete in a uniform texture. Over-blasting will result in reduced coverage rates of subsequent coats of primer and finish. Sweep and vacuum any remaining dust, dirt, or contaminants with a wet/dry vacuum. All dirt, foreign contaminants, and laitance must be removed to assure a trouble-free bond to the substrate.

Moisture Content Testing: After the floor has been cleaned and abraded, moisture content tests are highly recommended. Three (3) tests are required for the first 1,000 S.F. and an additional test for every additional 1,000 S.F. in accordance with ASTM F1869 Standard Test Method for Measuring Moisture Vapor Emission Rate of Concrete Subfloor Using Anhydrous Calcium Chloride Moisture Emissions Test. Other acceptable test methods are ASTM F2170 In-Situ Probes or ASTM F2659 Non-Destructive Electronic Moisture Meters. The moisture content must be less than four (4) pounds (4%) of moisture per 1,000 square feet per 24 hrs. for the standard converter. The 5751 Epoxy Vapor Barrier and 5752 Epoxy Fast Set Vapor Barrier Activators are more surface tolerant and can withstand up to 25 pounds of moisture per 1,000 square feet per 24 hr.

Crack Filling & Patching: Patch divots in the floor with a slurry of AP-91000 AllPro Epoxy and sand or aggregate, AP-91024 AllPro 100% Solids Fast Set Crack Filler or an approved patching compound. Fill cracks with SP-91024 AllPro 100% Solids Fast Set Crack Filler or AllPro Polyurea Crack Filler in accordance with the product data sheet. Expansion joints shall be filled with an approved joint sealant.

POT LIFE: THIS PRODUCT HAS A VERY LIMITED POT LIFE. MIX ONLY WHAT CAN BE USED IN THE INDICATED TIME TO AVOID ANY LOSS. **NEITHER COMPONENT WILL WORK UNLESS MIXED WITH THE OTHER! Must combine Part A & Part B, sold separately.

Do not re-use containers that have been converted or mix with previously catalyzed material.

Thinning: DO NOT THIN! Thinning is not necessary.

Mixing Tools & Speed: Use a paddle mixer and a variable speed drill at low speed (300 to 450 rpm). Take care not to whip air bubbles when mixing as the bubbles will be difficult to remove once the product is applied to the concrete floor.

Related Products

-

AllPro Epoxy Floor Coatings, 100% Solids, Part B, Standard Activator, 1 Gallon SKU: AP91010B$90.00each

AllPro Epoxy Floor Coatings, 100% Solids, Part B, Standard Activator, 1 Gallon SKU: AP91010B$90.00each -

AllPro Epoxy Floor Coatings, Universal Color Pods, 1 Liter SKU: APUNIVERSALCOLORPODSAs low as $29.00each

AllPro Epoxy Floor Coatings, Universal Color Pods, 1 Liter SKU: APUNIVERSALCOLORPODSAs low as $29.00each -

AllPro Epoxy Floor Coatings, 100% Solids, Part B, Standard Activator, 1 Gallon SKU: AP91010B$90.00each

AllPro Epoxy Floor Coatings, 100% Solids, Part B, Standard Activator, 1 Gallon SKU: AP91010B$90.00each -

AllPro Epoxy Floor Coatings, Universal Color Pods, 1 Liter SKU: APUNIVERSALCOLORPODSAs low as $29.00each

AllPro Epoxy Floor Coatings, Universal Color Pods, 1 Liter SKU: APUNIVERSALCOLORPODSAs low as $29.00each -

AllPro Epoxy Floor Coatings, 100% Solids, Part B, Standard Activator, 1 Gallon SKU: AP91010B$90.00each

AllPro Epoxy Floor Coatings, 100% Solids, Part B, Standard Activator, 1 Gallon SKU: AP91010B$90.00each