Simiron 85% Solids Polyaspartic High-Performance Floor Coating Clear Topcoat, High Gloss, 1.5 Gallon Kit

SIMIRON 85% Solids Polyaspartic is a two-component, high performance, high gloss, fast-drying, aliphatic polyaspartic floor coating designed for application over full broadcast systems. It provides superior protection through its excellent adhesion, durability, and resistance to stains, chemicals, and damaging UV rays.

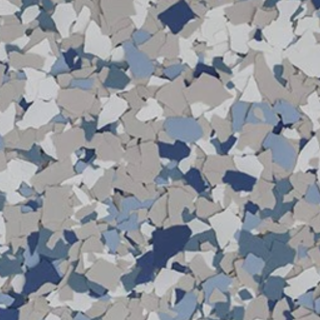

SIMIRON 85% Solids Polyaspartic can be applied up to 16 mils thick in a single pass to seal floors broadcast with Decorative Chip, decorative quartz and silica sand. It can be applied in a wide range of temperatures and dries to a hard, non-yellowing finish with superior chemical resistance that can be used in both indoor and outdoor applications. Because of the high build that can be achieved in a single pass, and the wide range of application temperatures, installation, and return to service time is greatly reduced over other coatings.

Recommended for: High Traffic Areas, Cold Storage Areas, Food Processing facilities, Residential & Commercial Garages, Industrial Factories & Warehouses, Commercial Kitchens, Cafeterias, Exterior Applications, Walkways, Pool Decks & Other UV Exposed Areas, Topcoat or Finish Coat for Other Floor Systems, Topcoat or Finish Coat for Floors Broadcast to Refusal with Decorative Chip, Quartz, or Silica Sand.

- Interior/Exterior

- Clear topcoat-High Gloss Finish

- Easy-to-Clean

- Resists Abrasion and Scratches

- Superior Chemical Resistance

- UV Stable — 85% Solids

- Non-yellowing formula

- Fast Return-to-Service

- Zero VOC

- LEED Compliant

| Type | Interior/Exterior |

|---|---|

| Size | 1.5 Gallon |

| Color | Clear |

| Coverage | 100-160 Sq. Ft. per gallon |

| Brand | Simiron |

| Finish | High Gloss |

| Material | 85% Solids Polyaspartic |

| Manufacturer Code | 40005559 |

Surface Preparation: Concrete and coated concrete surfaces must be sound, clean, dry and free of contaminants such as dirt, dust, grease, oil, silicones and other contaminants that may negatively affect adhesion.

Moisture Vapor Barrier: A suitable moisture barrier must be in place for concrete slabs on-grade. If a moisture barrier is not in place, seasonal variations in ground moisture can cause excessive moisture vapor transmission (MVT) regardless of results measured prior to coating application. MVT rate must not exceed three pounds per 1,000 square feet per 24 hours, as directed by ASTM F1869. The relative humidity (RH) of the slab must not exceed 75%, as directed by ASTM F2170. If there is a moisture situation in excess of the above rate, the use of Simiron MVB Moisture Vapor Barrier Primer may be required. Consult a Simiron Representative for details and application procedures.

Application:

- Apply at a spread rate of 100-160 square feet per gallon to yield 10—16 wet film thickness using a squeegee and back-roll with a non-shedding 3/8 in. nap roller.

- In hot or humid conditions, apply via 18” roller in a dip and roll method from a roller pan as increased heat and humidity will decrease the working time of the material.

- This material will cure faster with exposure to moisture in the air.

- To avoid visible differences in texture or mix-to-mix “tie-ins” do not exceed 5–10 minutes from one mix to another.

- Use joints as natural breaks to divide sections of the floor.

- If less texture is desired for a broadcasted floor, apply a second coating of 6–8 mils (no more than 200 Sq. Ft. per gallon) on top of the previous coat as soon as it is tack free. Applying thicker than recommended, allowing material to pool, or rolling into late may leave a white, hazy appearance.

New/Bare Concrete: Diamond grind or shotblast to a CSP 1-3 surface profile. Refer to SSPC-SP13/NACE 6 or ICRI Technical Guideline No. 310.2. New concrete must be cured a minimum of 28 days and should meet moisture vapor transmission (MVT) and relative humidity (RH) thresholds as described in Surface Preparation section.

Previously Coated Surfaces: This product is only designed to seal full broadcast systems. Thoroughly sand/grind with 60 grit sandpaper or diamonds and clean existing coating to provide proper surface profile and proceed with application of a full broadcast system per manufacturers instructions.

Dry Time: Open working time: 30-35 Minutes, Tack free: 2 Hours, Light Foot Traffic: 6 Hours, Heavy Traffic: 48 Hours, Full Cure: 5 Days. Ideal temerature range for application Air Temp: 45°–95°F, Surface Temp: 45°–95°F, Material to be applied: 60°–85°F. Higher temperatures will shorten the pot-life and open working time with material. Floor temperature must be at least 5 degrees over the current dew point.

Coverage: 100-160 Sq. Ft. per gallon at 10-16 mils applied. Use a mil gauge to make sure of proper application thickness.

Clean Up: Clean up mixing and application equipment immediately after use with acetone or xylene; do not use alcohol. Follow solvent manufacturer’s safety instructions. Be sure to follow all local, state and federal regulations when disposing of materials.