Simiron 1150FC 100% Solids Fast-Cure Floor Epoxy, Base Part A Only, Haze Gray, 2 Gallon

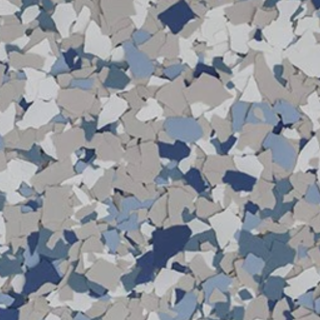

Simiron 1150FC is a 100% solids, zero VOC, fast-cure epoxy primer. 1150FC allows users to achieve a fast return to service flooring system. Combine with Decorative Chip or quartz flooring systems to create an attractive and durable finish that can be applied in a day. Use with Polyaspartic HS Fast Cure at temperatures as low as 35°F (2°C).

Recommended to prime and build under other SIMIRON products where fast cure is needed. Apply 16 mils total for moisture vapor tolerance. Use in combination with fast-cure products from SIMIRON for installation in cool conditions.

- Interior

- Part A Base Haze Gray Only

- 100% Solids

- Zero VOC

- Solvent Free

- Durable

- Excellent Adhesion Properties

- Impact Resistant

- Fast curing formula for quick return to service

- Resistant to Moisture Vapor Transmission up to 12 lbs. per ASTM F1869 or 85% RH per ASTM F2170.

| Type | Interior |

|---|---|

| Size | 2 Gallon |

| Color | Haze Gray |

| Coverage | 100-533 Sq. Ft. per gallon |

| Brand | Simiron |

| Material | 100% Solids Epoxy |

| Manufacturer Code | 40002817 |

Surface Preparation: Concrete and coated concrete surfaces must be sound, clean, dry and free of contaminants such as dirt, dust, grease, oil, silicones and other contaminants that may negatively affect adhesion.

Moisture Vapor Barrier: A suitable moisture barrier must be in place for concrete slabs on-grade. If a moisture barrier is not in place, seasonal variations in ground moisture can cause excessive moisture vapor transmission (MVT) regardless of results measured prior to coating application. 16 mils MVB is resistant to MVT up to 25 lbs. per 1000 Sq. Ft. in 24 hours per ASTM F1869 or 95% RH per ASTM F2170.

Application: 1150FC mix ratio is 2 Parts Base to 1 Part Activator by volume.

- Pre-mix Base at low speed for 1 minute. Pour base into a 2—5 gallon mixing pail. If pigmenting, mix E-Tint into the Base. Then, add Activator and mix for three minutes until uniform. Do not mix more material than can be applied in 10–15 minutes (material will stiffen or tack-up).

- Immediately pour all mixed 1150FC on the floor in a long bead approximately 8–12 inches wide. Do not attempt to roll material out of a bucket or roller pan.

- Wearing spiked shoes, spread evenly at 3–8 mils by pushing a flat squeegee or metal spring blade along the bead. Overlap previous passes in order to ensure concrete pinholes are filled. A tight, thin coat of primer with no backroll is the best way to minimize outgassing bubbles.

- If back-rolling, use a non-shed 3/8” roller and back-roll the primer evenly across the squeegee passes to minimize application lines and leave a consistent film thickness.

- Before overcoating, inspect the applied and set MVB for pinholes or voids from displaced air or inadequate patching. Sand and recoat if needed. Thickened MVB may need to be used to patch more severe holes or cracks.

- After the 1150FC Primer has set, apply the balance of the material to equal 16 mils total in order to get tolerance to Moisture Vapor Transmission up to 12 lbs. per ASTM F1869 or 85% RH per ASTM F2170. Use a flat or notched squeegee to spread the material and back-roll to reduce squeegee lines and even out the material.

New/Bare Concrete: Diamond grind or shotblast to a CSP 3 or greater surface profile, depending on total thickness of system. Refer to SSPC-SP13/NACE 6 or ICRI Technical Guideline No. 310.2. New concrete must be cured a minimum of 28 days and should meet moisture vapor transmission (MVT) and relative humidity (RH) thresholds as described previously in Surface Preparation section.

Previously Coated Surfaces: Clean surface to prevent any contaminants from being spread/redistributed to a greater area being prepared. Completely remove previous coatings, sealers, joint fillers, and patching materials. Diamond grind or shotblast to a CSP-3 or greater surface profile. Refer to SSPC-SP13 / NACE 6 or ICRI Technical Guideline No. 310.2.

Dry Time: Open working time: 10-15 Minutes, Tack free: 2.5 Hours, Light Foot Traffic: 5 Hours, Full Cure: 5 days, Minmum Recoat: 4 hours, Maximum Recoat 24 hours, Heavy Traffic: 48 Hours, all subject to ideal surface & air temerature with relative humidity of 72°F (25°C) 50% RH. Ideal temerature range for application Air Temp: 45°–95°F, Surface Temp: 45°–95°F, Material to be applied: 60°–85°F. Higher temperatures will shorten the pot-life and open working time with material. Floor temperature must be at least 5 degrees over the current dew point.

Coverage: Mixed 1150FC is applied at a nominal 3-16 mils ( 100-533 Sq. Ft. per gallon).

Clean Up: Clean up mixing and application equipment immediately after use with acetone or xylene; do not use alcohol. Follow solvent manufacturer’s safety instructions. Be sure to follow all local, state and federal regulations when disposing of materials.