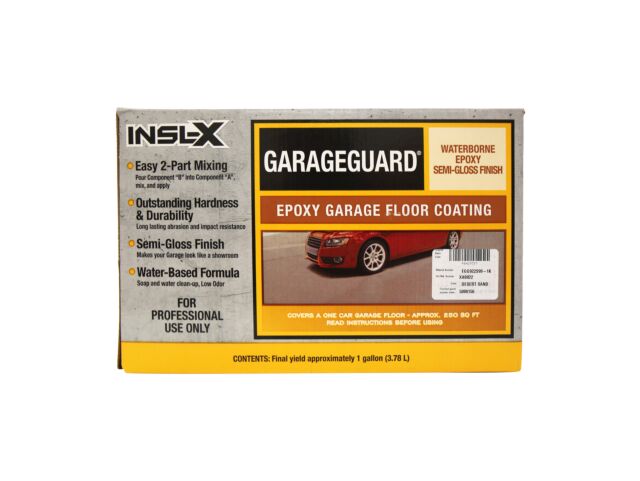

INSL-X Garage Guard Waterborne Floor Epoxy Semi-Gloss, Desert Sand, Gallon Kit

- For Garage Floors, Basement Floors, and other concrete surfaces

- Resists most automobile fluids

- Abrasion and impact resistant

- Soap & Water Clean-Up

- Easy to Clean

- Non-skid properties can be used as needed

| Type | Interior |

|---|---|

| Size | Gallon Kit |

| Color | Desert Sand |

| Brand | INSL-X |

| Series/Sub-Brand | Insl-X |

| Finish | Semi-Gloss |

| Material | Water-Based |

| Manufacturer Code | EGG-922S |

Surface Preparation: Sweep all dirt and trash from the surface. Scrub floor with a stiff brush and strong detergent solution to remove all dirt, grease, oil and other contaminants. Scrub grease and oil spots with an Oil & Grease Emulsifier. Scrub the floor a section at a time (10’ by 10’) and thoroughly rinse each section before moving on. Once the entire floor is clean, rinse the floor thoroughly with clean water and allow to dry completely. Use a squeegee, if necessary, to remove ponded water. Previously Painted Floor: Loose or damaged concrete and cracks must be filled with a suitable concrete based patching material. Remove all loose materials and dust. Remove loose or peeling paint by sanding and scraping. Feather the edges to attain a smooth look to the finish coat. Test the remaining paint for adhesion. Cut an X in the paint with a single edge razor blade. Apply duct tape firmly to the floor directly over the X. Remove the duct tape with one quick pull. If more than 25% of the paint at the X is removed, do not apply GarageGuard® until all existing paint is removed. Do not use muriatic acid or other etching materials on a painted floor.

Floor Never Painted: Allow new concrete to cure for a minimum of 30 days. Loose or damaged concrete and cracks must be filled with a suitable concrete based patching material. Be sure to smooth the patch completely. Allow to dry in accordance with the manufacturer’s instructions. Remove all loose materials and dust. All bare concrete floors need to be acid etched with a concrete etching solution or a 10% muriatic acid solution to open and roughen the surface enough to assure good adhesion and to neutralize the alkali salts. Follow the manufacturer’s instructions and safety precautions. Be sure to protect your eyes (goggles) and skin (rubber gloves and boots) while preparing and using any acid solution. Neutralize the acid according to instructions on the etching solution package –or- mix 1 lb. of baking soda in 5 gallons of clean water and distribute over the floor. Thoroughly rinse the floor with clean water and allow to dry thoroughly (at least 24 hours). Check for dryness using a moisture meter specific to masonry surfaces (2% moisture content or less) or ASTM D-4253 Plastic Sheet Test. Tape down a clear piece of plastic to the concrete floor for 24-48 hours; if moisture collects or slab has darkened the moisture/vapor transmission is too high to accept a coating and will need additional drying time. The floor should have a roughened feel of about 80 grit sandpaper. Please consult Technical Service for other surface preparations or for use in severe environments.

Notes: All glossy surfaces can be slippery. Where nonskid properties are required, a non-skid additive should be used. All epoxy coatings will chalk and fade if applied on exterior surfaces subjected to direct sunlight. Under certain environmental conditions, epoxy coatings will yellow. They can also stain with prolonged exposure to brake fluid. This staining will not affect the durability or protective qualities of the coating. Garage Guard will not sure at a surface temperature below 50°F. Not recommended for use in immersion service or acidic exposures.

Application: Mix each individual component thoroughly prior to inter-mixing the two. ”A” and “B” must be combined together (3:1 ratio) and thoroughly mixed. The use of a drill mixer at low speed is required to accomplish this task. Then allow the mixture to induct for a period of 30 minutes. This induction time is critical and should be the same for all kits. Do not mix partial containers. Do not mix more material than can be used in 4 hours. Thin with water ONLY. Do not exceed 10% reduction. Airless Spray: Tip range 15 - 19 thousandths. Total fluid output pressure at tip should not be less than 2100 psi. Air Spray (Pressure Pot): DeVilbis MBC or JGA gun, with 704 or 765 air cap and Fluid Tip E. NOTE: Do not allow material to remain in hoses, gun or spray equipment. Thoroughly flush all equipment with recommended thinner.

Coverage: 250 - 300 Sq. Ft. per gallon

Clean-up: Clean brushes, rollers and other equipment with soap and water immediately after use.

Dry Time: Tack free 2 hours, To recoat- 8 hours, Return to service: foot traffic 24 hours, vehicular traffic-72 hours cool tires, 5-7 days cure time to allow for hot tires.